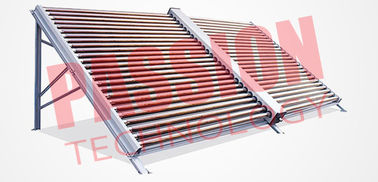

50 Tubes Powerful Thermal Stainless Steel Manifold Vacuum Tube Solar Collector for Hopsital

Description

non pressure solar collector evacuated tube , hot water supply with low cost

Solar Thermal is specialized in making solar vacuum tubes.

Tubes not only have different colors, but also have very stable film, which leads to a fast heating and an excellent heat preservation.

Solar vacuum tube assimilate the advanced 12 layers of spattering deposition of trivalent technology,high borosilicate glass, gradual change of CU/SS-ALN(H)/SS-ALN(L)/ALN selective complex absorptive coating.

And these make vacuum tubes have high performance of absorptance and low reflection ratio.

Through the inter layer,vacuum has a unique effect of thermal ,with its temperature up to 380°C of idle sunning,performing a strong heating ability.

Model and Data

| Model |

Vacuum tube

(D*L*N)

|

Aperature |

Collector volume |

40HQ loading |

20GP loading |

| PT-54/2.30/0 |

58*1800*18 |

2.30 |

54 |

161 |

69 |

| PT-60/2.60/0 |

58*1800*20 |

2.60 |

60 |

149 |

63 |

| PT-78/3.38/0 |

58*1800*26 |

3.38 |

78 |

124 |

54 |

| PT-90/3.90/0 |

58*1800*30 |

3.90 |

90 |

112 |

45 |

| Description |

Non-pressure solar collector |

| Material of inner tank |

0.4mm thickness SUS304/2B Food grade stainless steel |

| Material of manifold tank |

0.4mm thickness SUS304/BA stainless steel |

| Tank insulating layer |

40mm 50kg/m³ high-density polyurethane foam |

| Inlet and outlet hole |

Male G 1’ /NPT1' |

| Solar collector tube |

3.3 Borosilicate glass with ALN coating |

| Thickness of glass tube |

1.6mm |

| Vacuum tube tightness |

P≤0.005 Pa |

| Absorption |

as=0.93-0.96(AM1.5) |

| Emission ratio |

εh=0.04-0.06(80C±5C) |

| Idle sunning property parameters |

Y=220~260m2.C/KW |

| Average heat loss coefficient |

ULT=0.6~0.7W/(m2.C) |

| Bracket: |

Aluminum alloy with anti-corrosion treatment, 1.8mm thickness |

| Frame angle: |

15°/25°/27°/30°/35°/45°/52°

<Please select specific angle when you order>

|

| Welding: |

Argon arc welding, spot welding |

| Fastening pieces: |

Made of stainless steel screw |

| Frame angle: |

Nylon bottom support, silicon gasket |

| Max working temp.: |

99°C |

| Max pressure: |

0.005Mpa |

| Hail resistance: |

Ø25mm |

| Anti Freezing: |

-20°C |

| Wind resistance: |

20m/s |

| Instruction manual: |

Available |

How does solar vacuum tube work?

After installation and check the heating collector system correctly, cold water is filled in the water tank.

Due to gravity, cold water flowed into the vacuum tubes, absorbing the heat (which the temp. might reach 250 degree centigrade).

Cold water changes into hot water and goes back to the water tank.

Product Advantages :

1. Excellent material: High borosilicate glass 3.3 is adopted as the raw material.

2. High thermal efficiency: Pure vacuum layer without impurity. Degree of vacuum is high and lasts long, possessing extremely high absorption to sunlight with extremely low thermal emissivity.

3. Small thermal losses: Higher degree of vacuum is kept between vacuum heat collection pipes, reducing thermal losses caused by heat conduction and heat convection to the maximum.

4. Long life: Performance of film plated layer is stable, being not easy to aging and attenuation. Processes in links of material selecting, production, transportation and quality inspection, etc. are strict with longer service life.

5. Corrosion resistant: Performance against chemical corrosion is extremely good, appropriate to various kinds of water quality.

6. High degree cold resistant: Even in high latitude in Northeastern China area with high degree cold temperature bitter cold, hot water can still be used normally, displaying super high heat collection rate.

Shock Resistance Test:

Solar vacuum tubes can work in harsh environment. Hot water is available because of good vacuum tightness in cold weather. And also the borosilicate glass 3.3 can bear collision in a certain level. Photos below are a test about this.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!